From Automotive to Cleaning: Versatile Brush Machines Explained

From Automotive to Cleaning: Versatile Brush Machines Explained

Blog Article

In the ever-evolving landscape of manufacturing, the demand for versatile machinery is at an all-time high. One type of equipment that has gained significant attention is the brush machine, known for its ability to create a diverse range of products across various industries. From automotive applications that require precise and durable brushes to cleaning solutions that cater to residential and commercial needs, these machines are pivotal in meeting market demands.

At the forefront of this innovative technology is Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd., a distinguished company with 37 years of expertise in producing advanced brush machines. Specializing in 2-5 axis machines, Jiangmen Meixin has accumulated invaluable technical knowledge and experience, setting a standard in the brush manufacturing industry. In this article, we will delve deeper into the versatile capabilities of these machines and explore their significant contributions to both the automotive and cleaning sectors.

Company Overview and History

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. has established itself as a prominent leader in the brush machine industry. Founded over three decades ago, the company has consistently dedicated itself to the design and production of advanced machinery tailored for the brush manufacturing sector. With a focus on innovation and quality, Meixin has developed a diverse range of machines that cater to various applications, from automotive brushes to cleaning products.

With 37 years of production experience, Jiangmen Meixin has cultivated extensive technical know-how, allowing it to stay at the forefront of technology in the brush making machinery field. The company prides itself on its ability to adapt to evolving market demands and continuously improve its offerings. Its commitment to quality and reliability has earned Meixin a solid reputation among clients both domestically and internationally.

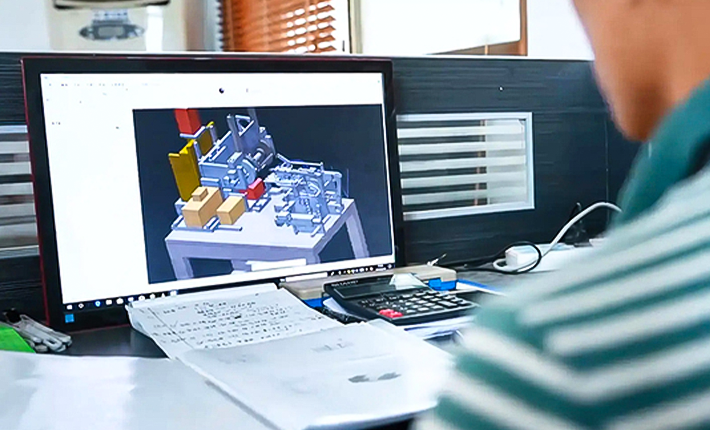

The company's expertise in 2-5 axis machines sets it apart as a manufacturing powerhouse. These machines not only enhance productivity but also ensure precision in the production process, enabling clients to achieve high-quality results. As the brush industry continues to grow, Jiangmen Meixin remains dedicated to leading the charge in innovation and excellence.

Technological Innovations

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. stands at the forefront of technological advancements in the brush machine industry. With 37 years of experience, the company has developed a range of 2-5 axis machines that are designed to enhance precision and efficiency in brush production. These machines utilize advanced automation and programming, allowing for the creation of intricate brush designs with minimal manual intervention.

The integration of smart technology has revolutionized operations at Jiangmen Meixin. With the implementation of real-time monitoring systems, manufacturers can now track production metrics, ensuring optimal performance and quality control. This not only minimizes waste but also streamlines the entire manufacturing process, making it more sustainable and cost-effective.

Additionally, the commitment to research and development has allowed Jiangmen Meixin to continuously innovate its product offerings. By collaborating with industry experts and investing in the latest materials science, the company is able to introduce features such as enhanced durability and versatility in their machines. This dedication to technological progress positions Jiangmen Meixin as a leader in the brush machine sector, catering to various industries beyond automotive applications.

Diverse Applications of Brush Machines

Brush machines have found their place in various industries, showcasing their versatility and adaptability. In the automotive sector, for example, these machines are essential for manufacturing interior and exterior brushes that cater to a range of cleaning and detailing needs. The precision engineering involved ensures that the brushes are durable, effective, and tailored for specific applications, enhancing the overall quality of automotive maintenance products.

In the cleaning industry, brush machines play a vital role in producing brushes used for both commercial and domestic cleaning. From floor scrubbers to specialized brushes for intricate cleaning tasks, these machines allow for the mass production of high-quality cleaning tools. Companies benefit from the efficiency and reliability of these machines, enabling them to meet the growing demand for effective cleaning solutions in an ever-evolving market.

https://mxbrushmachinery.com

Furthermore, the adaptability of brush machines extends to numerous other fields, including personal care and industrial applications. They are employed in the production of brushes for cosmetics, healthcare, and even machinery maintenance. The expertise of companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. has made it possible to produce specialized 2-5 axis machines that cater to the unique requirements of each industry, illustrating the significant impact and importance of brush manufacturing technology.

Manufacturing Process

The manufacturing process at Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. begins with the selection of high-quality raw materials. The company carefully sources various types of bristles and base materials to ensure durability and efficiency in the final product. This initial step is crucial, as the quality of raw materials directly impacts the performance of the brush machines. Each material is tested to meet industry standards before moving forward in the production line.

Once the materials are selected, they undergo an intricate preparation process. This includes cutting, aligning, and sizing the bristles according to specific machine requirements. The experienced technicians at Meixin utilize their 37 years of technical knowledge to optimize each step, ensuring precision and consistency. By employing advanced machinery during preparation, the production team can maintain high efficiency while minimizing waste.

Finally, the assembled machines undergo rigorous quality control checks before being packaged and shipped. Each unit is tested for functionality and durability, confirming that it meets the stringent standards set by the company and the industry. This final stage not only guarantees the quality of the machines but also enhances customer satisfaction, ensuring that clients receive a reliable product for their manufacturing needs.

Future Prospects

As the demand for specialized brushes continues to grow across various industries, the future of brush machine manufacturing appears promising. Companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. are well-positioned to capitalize on this trend, given their extensive experience and expertise in producing advanced 2-5 axis machines. The evolution of manufacturing technologies paves the way for increased efficiency and precision in brush production, enabling manufacturers to meet the diverse needs of their customers.

Innovation in materials and design will further enhance the capabilities of brush machines. As industries focus on sustainability and eco-friendly solutions, manufacturers are likely to adapt their machines to incorporate biodegradable materials and energy-efficient processes. This shift aligns with global environmental goals and presents opportunities for companies to expand their market reach, appealing to a more environmentally conscious consumer base.

Moreover, the integration of automation and smart technologies in brush machine production will redefine operational efficiencies. As production lines become increasingly automated, the potential for reducing labor costs and improving output quality rises. With Jiangmen Meixin's dedication to technological advancements, the company is expected to lead the charge in developing next-generation machines that will not only meet current market demands but also set new standards for the brush manufacturing industry.

Report this page